(A drag & push luggage trolley can do 3 works - LIFT, MOVE & PLACE the luggage)

INTRODUCTION:

Here is to a new device that lets you do LIFT, MOVE and PLACE your own luggage yourself with ease without depending porters/others while you are at the Air Port/ Railway and Bus Stations. Of course, the trolleys now available at the air Port/ Railway Stations can help us to carry our luggage. But this trolleys will not help us to lift the luggage from the conveyor belt in Air Ports/from Trains or to place it in vehicles. Now this Mechanical porter comes to your rescue and this single machine can do all this three works (LIFT, MOVE & PLACE) that a manual porter can do - so it is called Mechanical Porter.

Actually Mechanical porter replaces the need of lifting/placing the luggage because we can able to raise/lower the luggage platform of the trolley to the level/height of the luggage ( where as the plat form in the conventional trolley is fixed). Here all we have to do now is just DRAG or PUSH the luggage. So it is otherwise called DRAG & PUSH trolley. Even your small child can able to lift you to a height of 4 feet by just pedaling by hand or foot.

This machine is cost effective. It may be noted here that some kind of very costly lifting machines (with motorized hydraulic jockeys) are usage at industries. But this mechanical porter runs on simple mechanism without motors, batteries or costly hydraulic jockeys. Actually the commuters uses the trolleys occasionally for small movement of 5 to 10 minutes and thus there is no need of motorizing this machine. More over motorizing this machine make pollute the busy Air port/Railway stations besides makes it costlier and subject to periodical maintenance as well. Thus the pedaling system in this mechanical porter makes this machine not only cost effective but also maintenance free and power free and thus environmental free also. The applications of this machine is not only restricted with Air Port and Railway stations but also has wide range of usage at homes, Departmental stores and libraries as well.

AIM OR OBJECT OF INVENTION:

The rationale behind the construction of the model is the absolute necessity for avoiding the physical hard work in LIFTING and PLACING HEAVY LUGGAGES at the Air Port Railway Stations by the commuters( especially women &old age and Physically challenged people) from Train/Conveyor belt to trolley and trolley to car or to other vehicle.

THE PRESENT SYSYEM:

At the Air port or Railway Station or Bus stations, at present the trolleys are available, giving the helping hand to the passengers to carry the luggage from one place to another. Even then, the passengers find it very difficult to lift their heavy luggage from the conveyor belt (at Air ports) or from train or other vehicles to the trolley and from trolley to vehicles (outside the Airport/Railway Stations/Bus Stations). For this work, they have to be dependent on porters or some helping minded people. Lifting the luggage IN/OUT of trolley is more troublesome for the lady passengers, senior citizens and physically challenged people, especially when they travel alone. Likewise there is a risk of allowing strangers inside the house as the house wives at homes depending some body to lift and carry gas cylinders(30Kg) and water bottle(20 lt) and other heavy domestic things.

SOURCE OF IDEA:

I am Masha Nazeem, a girl student who designed this device. I used to go by air often to attend various science expos and seminars. At times, I had to travel alone. While entering into or coming out of the Air port, I felt it very difficult to lift the luggage at various points. The trolley available at Airports helps the passengers only to move the heavy luggage from one place to another. But lifting the same at various points at the Air Ports is something difficult for the passengers of above mentioned category. This problem exists not only in Indian Air Ports but also in all over the world including Dubai and Tokyo - the Air Ports I have visited so far. This led me to design �A Lift Carry & Place Trolley�, otherwise called MECHANICAL PORTER.

THE BASIC FACTORS IN DESIGNING THE MECHANICAL PORTER

While designing the Mechanical Porter the following concepts are taken in to account.

Economically viable. The present model of the trolley that is used in the Air port is very simple, and maintenance free. So the new solution should be even more simple, less maintenance and economical at the same time with more added facility.

Commercially viable. The model should be a commercially viable alternate to the existing model available in the market in terms of price.

Customer friendly: The targeted users of this product are weaker sections of the society. � such as old age people, physically challenged people, ladies and boys & girls. So the handling of the machine should be very easy.

Environmental friendly: The places where this machine actually put in use are thickly populated busy areas (Air port/Railway Station). So this machine should be environmental friendly. So the usage of motors or batteries should be avoided.

Exploiting users psychology: The people who use this machines are only occasional users. The pedaling work that they have to do is neither an additional job nor a full time job. As the passengers remain idle in their seat in a same position for a long time during their travel, they will feel happy to do this one minute easy manual work as a warming up exercise.

Universal application: A product should be successful if it has a domestic usage. So the design should be of universal application in domestic, libraries, departmental stores and Hospitals and now even the house wives can carry carrying gas, water bottles to kitchens without allowing strangers inside the houses.

HOW DOES IT HELPS IN LIFTING THE OBJECTS ?

With the help of this trolley, we can easily drag the luggage from the conveyor belt or from train coaches towards the trolley by moving the platform of the trolley to the desired height. Here we need not lift the luggage. All we have to do is just drag the luggage. Again by rotating the pedal we can move the platform little bit down and adjust the level of the already placed suitcase/box again to the level of the conveyor belt or train. Now, drag and load the second luggage and so on. Like wise, we can place the luggage in the car by pushing the luggage one by one by adjusting the level of the platform to the necessary height. Thus, by doing the simple things, �Drag & Push�, we can easily move heavy luggage from one place to another comfortably without straining much and without expecting help from others in lifting the same

CONSTRUCTION AND OPERATION OF SCISSOR MECHANISM

This machine is as same as the luggage trolley with slight modifications. In the existing trolley the luggage platform is fixed. But in the MECHANICAL PORTER, this Platform is movable with the help of steel plates arranged in a scissor like lifting mechanism. This scissors can be move up and down slowly by a rotation of a pedal. When we rotate the pedal clockwise, the platform of the trolley moves upwards and vice versa. Actually, when we activate through the pedal, it will move the scissor mechanism to move in a gliding bar and as this result the scissor move upwards/downwards. Thus with the help of scissor type mechanism we can able to raise the carriage platform to the maximum level of 4 feet by moving the sliding bar to just 4 inches along the stud by pedaling . So the user feel easier in lifting objects through this machine than lifting objects by hand directly.

CONSTRUCTION AND OPERATION OF GEAR SYSTEM WITH CABLE.

(Latest Model)

Here the platform tray is designed in such a way that it can be freely movable vertically up and down along the 3 feet high square pipe. The Platform tray is connected to a horizontal gliding bar with 2 rivets and connecting clamps so that the entire tray is lies in suspension on the gliding bar. Each end of the gliding bar is connected to a 6 inches high square pipe(movable) in such a way that this pipe is sliding up and down along the inside walls of the outer (fixed) square pipe. This horizontal gliding bar is connected to a steel rope at the centre and the other end is vertically fixed with a gear system. When the gear rotates the metal rope also rotates and get wound up in the bobbin of the gear box. This results in upward movement of the rope and the connected gliding bar and the tray upward and downward. The gear box enables lifting of heavy objects with effortless rotations of the gear box.

VARIOUS MODELS OF MECHANICAL PORTER:

1. Screw rod with Cycle pedal (Hand Pedaling):

Actually, when we activate through the hand lever, it will rotate a threaded steel stud or shaft which moves over a two bolts fixed on sliding bars. This two nuts are fixed on the centre of the sliding bars which slide over the U channels on either side of the stud. By movement of threaded stud by pedaling, the nuts get screwed along the stud which in turn move the two sliding bars in opposite direction. Actually the sliding bars moves in opposite direction when pedaling because the stud is threaded in such a way- half portion of the stud is threaded in clock wise direction and remaining portion is in anti clockwise direction. Thus, while pedaling the sliding bars moves equal distance in opposite direction. The advantage of double side- opposite threading minimizes the rotation of pedaling and provides stronger grip to the machine so that the machine can withstands even loading of heavy weights up to the maximum of 100 Kilos. The sliding arm (bottom rib) of the scissors type jack fixed on the either side of the sliding bars.

Result: This the first level model. Though this system works well it has some operational demerits. The use has to do as many as 30 more rotations to lift the object to 4 feet is high. As the hand pedaling system is connected by chain in upward direction, it causes inconvenience to the users. There are possibilities of staining of dresses of the user by the lubricants used in the chain and the dresses will get trapped into the chain at times. So to avoid this, foot pedaling system was developed.

Advantages

- Succeeded in lifting heavy object without much strain

Disadvantages

� Loss of energy due to pedaling from distance position.

� 40 pedaling rotation to achieve 3 feet height.

� Staining of dresses by the lubricants used in the chain.

� Weight of the trolley is very high.

Specifications

� Weight : 44 Kgs.

� No. of Threads in one inch : 8

� Thread Type : Normal (BSW)

� Scissor Type : Double step.

� Displacement of glide bars

to achieve 3 feet height : 4 inch

� Degree of rotation : 360 per rotation.

� No of Rotations : (40 Rotations)

� Pedaling : By hand

. Credits

National Level First Prize by NIF(National Innovation Foundation), ,Ahmadabad under Dept. of Science and Technology, Govt. of India.

2. Screw rod and spur gear system - (foot pedaling)

A spur gears system consists of 3 pair of wheels is fixed on the stud. The flywheel fixed in the gear system gets rotated while pedaling by foot. The fly wheel in turn rotates the gear system slowly. A shift liver is also fixed in the gear system to change the rotation of the stud to clockwise/anti clock wise. When we turn the shift lever to RIGHT side, the right wheel get contacted with the central wheel. As this right wheel rotates in clock wise direction it will in turn moves the stud and sliding arm forwardly resulting in the upward motion of the carriage platform. When we move the shift lever to LEFT side, the right wheel released and the left wheel get contacted with the central wheel. As the left wheel rotates in anti clock wise direction, the platform moves downwards while pedaling.

Specifications

Specifications

� Weight : 35 Kgs.

� No. of Threads in one inch : 8

� Thread Type :Normal(BSW)

� Scissor Type : Double step.

- Displacement of glide bars

to achieve 3 feet height : 4 inch

- Degree of Stroke : 35 to 40 per

� stroke.

Dis advantages

� The pedaling system in this model is as same as the system in sewing machine.

� The fly wheel system failed to give initial momentum to rotate the gear and the stud.

Result

� The fly wheel system fails to give initial momentum to rotate the gear and the stud. This model abandoned.

3. Screw rod and Ratchet wheel system-( foot pedaling)

Here a ratchet wheel is fixed directly on the screw rod . The screw rod gets rotated by pedaling the arms of the ratchet wheel.

Specifications:

�

Weight : 30 Kgs.

� No. of Threads in one inch: 4

� Thread Type : ACME

� Scissor Type : Three step.

- Displacement of glide bars to

achieve 3 feet height : 1 inch

- Degree of Stroke : 35 to 40 per

Stroke.

Advantages

- Foot pedaling is very easier to the user. So work load reduced.

- Load directly applied. So there is no loss of energy

- ACME Thread used. So movement of gliding bars along the stud faster.

- Displacement of gliding bars to achieve 3 feet height is just 1 inch.

- Three step scissors used. This minimizes the pedal strokes.

- Foldable handle bar facility. So easy portability of Trolley.

Disadvantages

- Friction in the rib during the initial upward movement.

Credits

First Prize in International Competition - Kurushetra - Conducted by Anna University under the patronage of UNESCO

4. Cable and Gear system using scissor mechanism( hand pedaling ):

The chain block gear system is used here as lifting mechanism. For this the input and out puts of the chain blocks are further modified and adopted here. The input has been modified as the hand lever and the out put of the chain block system has been modified into the space for roller wherein a steel cable wound up when we rotate the pedal. When we rotate the hand pedal clock wise the steel cable which is connected with the scissor mechanism through 3 pulleys in turn moves the stud of the scissor mechanism up wards. When we rotate the hand lever anti clock wise direction, the scissors comes to downward position. Thus with the help of steel cables and the modified chain block we can lift heavy objects up and down easily.

Advantages

� The number of rotations has been reduced to 12.

� Very easy to lift heavy objects.

� Foldable handle bar facility. So easy portability of Trolley.

Specifications:

Specifications:

- Weight : 30 Kgs.

� No. of Threads in 1 inch : Cable System

� Thread Type :Cable System

� Scissor Type : Three step.

- Displacement of glide bars to

achieve 3 feet height : 2 inches

� Degree of rotation : 360 per rotation.

(12 Rotations)

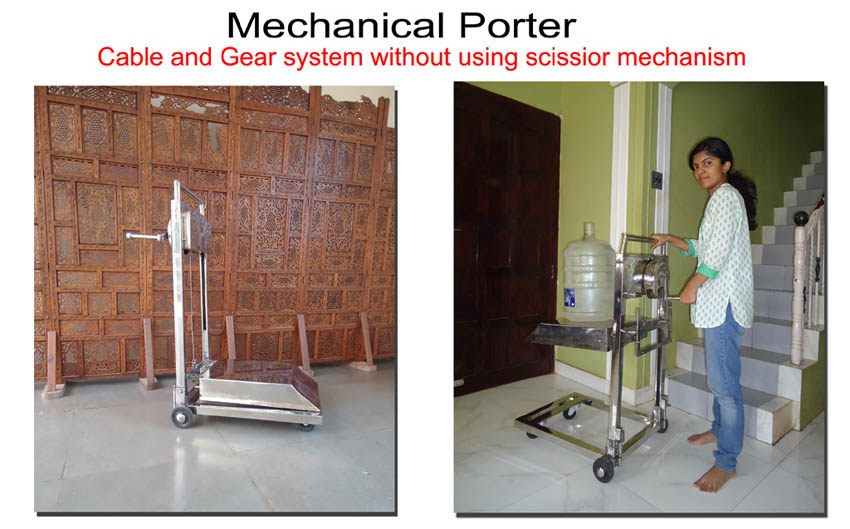

LATEST MODEL

5.Cable and Gear system without using scissor mechanism( hand pedaling )

Here the platform tray is designed in such a way that it can be freely movable vertically up and down along the 3 feet high square pipe. The Platform tray is connected to a horizontal gliding bar with 2 rivets and connecting clamps so that the entire tray is lies in suspension on the gliding bar. Each end of the gliding bar is connected to a 6 inches high square pipe(movable) in such a way that this pipe is sliding up and down along the inside walls of the outer (fixed) square pipe. This horizontal gliding bar is connected to a steel rope at the centre and the other end is vertically fixed with a gear system. When the gear rotates the metal rope also rotates and get wound up in the bobbin of the gear box. This results in upward movement of the rope and the connected gliding bar and the tray upward and downward. The gear box enables lifting of heavy objects with effortless rotations of the gear box.

Advantages

� The number of rotations has been reduced considerably.

�

Effortless rotation even to lift very heavy objects

� Foldable handle bar facility. So occupies less floor

space and easy portability.

� Market ready sleek model.

� Simple maintenance free mechanism.

� Less weight but lift heavy objects.

ADVANTAGES OF MECHANICAL PORTER

1 MECHANICAL PORTER is a very useful device and will be very handy to use in Airports, Railway Stations, Bus Terminals, Hospitals etc., to lift and move heavy luggage and baggage.(Refer photograph)

2 MECHANICAL PORTER has various other domestic applications also. Now the home care takers can lift, carry and place the heavy objects such as gas cylinders(30Kg), mineral water(20 liters cane) to the height up to 4 feet very comfortably without the help of others. Thus handling of heavy material at homes becomes easier.(Refer Photograph)

3 Also this MECHANICAL PORTER has wide range of utilities in commercial departmental stores, and central libraries in the educational institutions etc.

4 At present, no such multi purpose devices, for lifting, carrying and placing the objects simultaneously, in the above mentioned places, are available anywhere in the world.

5 This machine is cost effective. In large scale production the price may lesser than the conventional trolleys.

6 Actually the commuters uses the trolleys occasionally for small movement of 5 to 10 minutes and thus there is no need of motorizing this machine. More over motorizing this machine make pollute the Air port/railway stations besides makes it costlier and subject to periodical maintenance as well. Thus the pedaling system in this mechanical porter makes this machine not only cost effective but also maintenance free and power free and thus environmental free also Mechanical porter is Environmental friendly.

The platform tray freely movable vertically up and down along the square pipe.

The Platform tray is connected to a horizontal gliding so that the entire tray is lies in suspension on the gliding bar.